What can a Building Technologist do about Climate Change?

Title inspired by Bret Victor’s piece “What can a Technologist do about Climate Change?“

Something that has been swirling in my mind lately: personally having a more direct impact on our quest to reduce the causes of climate change. While I’ve been indirectly involved in environmental endeavors for most of my career, I naively thought I had more “time” to offer a more direct contribution. Don’t get me wrong– I think indirect contribution is incredibly important. (By “indirect,” I mean (1) influencing the necessary conditions that surround more “direct” activities today, and (2) the long term bets that will ultimately have direct impact, paving the way for new technologies and policies and cultural shifts in the future.) However, it feels like the time is now to deliver more directed contribution. [*]

So how does one go about determining what to spend one’s time on? Below, I lay out the recipe of my own search to answer that question.

Step 1: What do I want to impact?

I want to make a tangible contribution to our possibility of achieving a less than 2° C near-term future. I feel that our efforts in the coming decade will be a big determinant in that outcome. The time to direct attention is now.

Step 2: What are the biggest contributors, globally? How do my background and interests overlap with this?

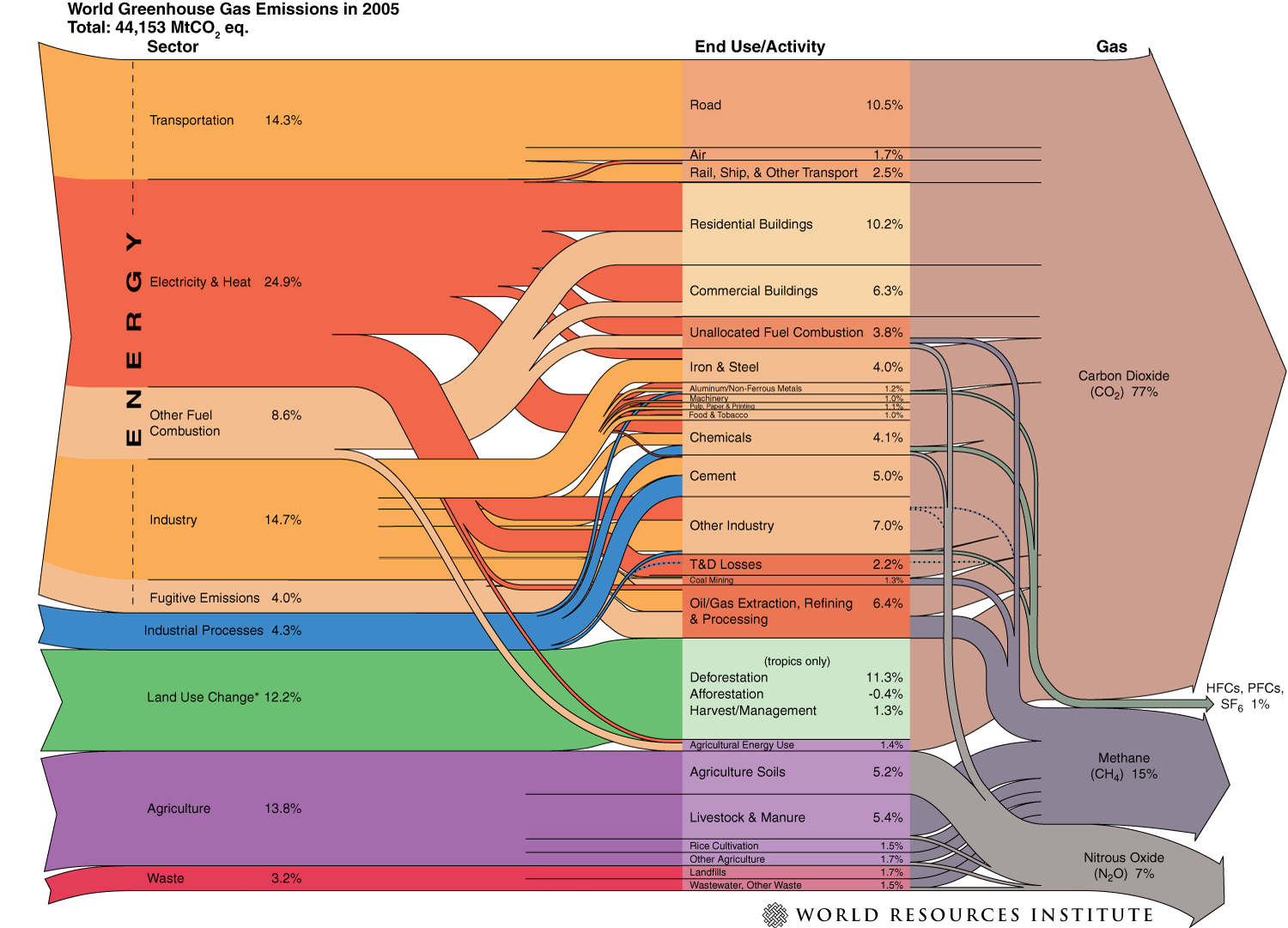

Let’s start with this World Resources Institute flow chart of world greenhouse gas emissions from 2005. I imagine models have been updated in the past 15 years, but this should be directionally right. [**]

Outsized impacts include Road transport (10.5%), Buildings (16.5%), Industry (cement, iron/ steel, chemicals alone are 13.1%), and Agriculture (13.8%). Deforestation is also a major contributor (11.3%).

How do these sectors interact with my background and interests? I know plenty of people interested (and working in!) Transportation, Agriculture, and Deforestation sectors… but MY interests are in Buildings and Industry. I have more experience in Buildings, so I’ll focus there for now.

Let’s dig a little more into the Buildings sector. This time, let’s look along the parameter of energy related CO2, from a recent report from UNEP. Building operations account for 28% of energy-related CO2 emissions. Building construction (including energy related emissions for processing materials like cement and steel) accounts for 11%.

Hmm what’s missing here? Something not discussed as often– the contribution of global warming from other greenhouse gases (GHG). As we look at this broader problem, let’s make sure to not ignore the other GHGs that buildings contribute to.

Also missing: Negative GHG technologies. Technologies that don’t just mitigate, but actually remove carbon from our atmosphere. Let’s ensure that our attention to emitting industries also keeps an eye towards reduction opportunities as well.

Sidebar: Global Warming Potentials

Remember that World Resources Institute chart from earlier? It reflects GHG as a percent of total gas… but it does not incorporate the weighted impact of their Global Warming Potential (GWP). See the comparison below.

In sum: CFCs have a huge GWP. Refrigerant management is thus a critical activity to mitigate the effects of climate change; Project Drawdown ranks it as THE solution with the greatest potential. See more from this paper from Lawrence Berkeley National Lab on opportunities related to lower GWP room air conditioners. The good news: 90% of refrigerants are released at the end of equipment life and they can be reclaimed/reused…. but that’s an operational & maintenance problem. (Hopefully, one humans can solve. We’ve done it before with the Montreal Protocol.)

Step 3: What does the current landscape look like?

Let’s look at energy related CO2 emissions for buildings, both residential and commercial. End use activities include space heating, water heating, lighting, cooking, and appliance & electronics energy use.

Here’s an overview from the United States:

Source: United States Mid-Century Strategy for Deep Decarbonization

Globally there’s lots of potential for improvement across end user activities, as shown here:

Although– I have a decent amount of concern for our past 2 decades of space cooling (counter)progress.

There’s an important point to make here that often gets glossed over. Aside from cars, think about the energy that you use personally. I’ll go first. Each morning when I wake up, I turn on the lights. If I live in California and its been smokey with forest fires, I’ll probably make sure that my air purifier is still on. If I live somewhere colder, I might turn up the space heater. Or, if hotter, turn up the air conditioner. I’ll ask my Amazon Alexa to play the news. I’ll take a shower with hot water. I’ll fry some eggs on the stove. I’ll then head out to the office; perhaps taking my electric vehicle that had been charging in front my place of residence. Once at the office I use the elevator to get to a top floor. I use the building controls to turn on the lights, or to make my workspace warmer or cooler. I charge my computer and monitor. These activities are now all part of our normal lives. And, these are the activities that are associated with building end use CO2 emissions.

My point:

✨ Addressing building related CO2 emissions is not just about architectural design & construction of new buildings. It’s about the whole system of buildings, the base for our personal energy use and the framing for our well-being as occupants.✨

Step 4: What possible solutions have already been identified?

We know that we need to decarbonize the grid and electrify buildings at the same time. But what does that mean specifically? Is that everything? Project Drawdown has a good place to work from here. They list the top “Buildings & Cities” solutions as follows:

As we can see, we have the technologies at workable cost, for the most part. But what are the hurdles to these technologies taking hold? Is it building codes and standards? Is it lack of sexyness and status? And/Or– as I suspect is likely the culprit– is it misaligned incentives across a decentralized industry?

Something that catches my attention (aside from the high cost of insulation solutions!) is that according to Project Drawdown, “Building retrofits” and “Net zero buildings” have no predetermined emission reduction potentials, no costs, no savings associated. Instead, we see a big fat “N/A.” The team behind Project Drawdown says that the difficulty in making projections like this is due to the high level of variety on such projects. In other words– projects in the building industry are so one-off and location/project specific that we flounder at generating the data needed to inform further decision making. If this impacts big picture data analysts, surely the problem eludes the actual industry as well…

Step 5: What’s the nature of the market surrounding that sector?

The particular nature of the Building Industry is artfully described in Dana Sheffer’s work from 2010. She makes three key points that I find to resonate:

- The building industry is Decentralized, different from the aerospace or automobile industries which are Centralized with leading firms. This means that in order for players within the building industry work together, “disparate firms need to self synchronize.”

- Modularity allows for change, subsystem by subsystem, but overall architectural change is *much* more difficult (this builds on Henderson & Clark 1990).

- There are at least three layers of existing fragmentation in the building industry: vertical, horizontal, and longitudinal.

In my opinion, there are thus three types of innovation pathways in the Building Industry:

1. Address modular components. This is what I call “black box strategy”– change out an existing component for one with different internal parameters, like purchasing a more efficient refrigerator or by specifying a “smarter” elevator.

2. Address interfaces. For new technologies or new construction methods that require a change not just to components but to the interfaces between components, it may be more effective to integrate at one or more level (Sheffer shows in her dissertation that greater integration correlates with greater technology diffusion). By bringing once-siloed steps in-house, the power of the lead-firm can now take hold.

3. Address architectural change. Rather than address the components or linkages between components, address the structure of the whole system instead; the hardest option of them all. What first comes to mind is Standards (and building codes*) and Status (like marketing-based certifications like LEED) but I sense that there is something much more powerful possible. Something like new mechanisms to transfer costs and value in novel ways?

*Do I sense an exploratory post on Building Codes in the near future?

Step 6: With all of this status quo– what’s preventing what you think SHOULD be true?

Let’s go through some of the possibilities explored above. What kinds of questions would I ask to explore the idea: What’s preventing what is possible; is this really the best we can do? Is it a lack of technologies? Costs that are too high? Policy barriers? Cultural barriers? Coordination pitfalls? Or something else…

Address modular components.

- Air conditioning. As more people around the world move to cities and can afford (and need) air conditioning– global AC sales grew globally by 16% in 2018— what does this mean for the circulation of refrigerants? For electricity use at peak demand? Low cost technologies are out there– see the LBNL paper referenced above– but why aren’t they being adopted? Should ventilation technologies for healthy indoor air quality (IAQ) be aggregated with temperature conditioning, or should they be separate?

- Space heating. What’s preventing electrified heat pumps from achieving a greater install base? When electrification isn’t an option: what opportunities exist for carbon neutral fuels?

- Water heating. What are the hurdles to electric boilers, both residential and commercial (install + operations)?

- Lighting. What’s slowing the proliferation of LEDs? (Is it really slowing?)

- Building controls. What opportunities exist in the residential market (beyond Nest)?

Address interfaces.

- Integrated firms. For all the recent companies tackling the building industry in an integrated way– say the product people of WeWork, those at Katerra, and others– what have they learned? What still remains a challenge?

- Interface-dependent technologies. For new technologies that are not modular, but must be introduced across interfaces– for example, decentralized water purifiers for buildings like from Zero Mass Water— what specific hurdles have they run into during sell & install? Extending beyond the building to demand-response grid scenarios, what are the hurdles to implementing new tools or protocols like VOLTTRON?

Address architectural change.

- Standards. What can be done with respect to building codes (commercial, residential, existing, energy, etc) at the model, state, or city level? What might be preventing these changes?

- Status. For all my jaded feelings about LEED the program really impacted the industry, globally, for the better. What have been some of their lessons learned? On a different note: How are established crafts / trades changing today in ways that could lead to opportunity or greater challenge? What might an ethnographic investigation tell us?

- Transfer mechanisms. What other transfer mechanisms (contractual, free market) opportunities are out there? This, I believe, has the most potential and yet is the thing that no one talks about. Solutions to address the split incentive / broken agency problem inherent in buildings.

Step 7: Let that simmer. And then go talk to people!

Now go seek out the answers to your questions above. (And make sure to do so globally!)

Conclusion

You’ll notice that my questions are oriented around the operations of buildings. That’s by design– I think the zeitgeist focuses on the creation of the new but we tend to overlook the operations and maintenance of the existing. And yet, this is where the greater costs are; buildings have a 50-100 year lifetime. How can a better understanding of O&M not only lead to better O&M in practice, but to smarter initial design (and transfer mechanisms) in the first place?

Source: United States Mid-Century Strategy for Deep Decarbonization

There are many possible pathways to have an impact– the question is which ones are meaningful. What we’re still missing, to quote Bret Victor, is “a tool that lets [us] skim across entire fields, browsing problems and discovering where [we] could be most useful.” In the absence of such tools, we create our own and share with others along the way. Hopefully this framework is useful to others who are considering what to direct their time and attention to.

fin

APPENDIX

For further evaluation of the landscape, Harnessing Complexity by Axelrod & Cohen has a great framework to think through complex, system-based problems. The framework asks:

- What are the ___ of the system? (strategies, agents, artifacts, rules of thumb, routines, norms, tools / resources)

- What are the populations of agents? How would they classify others, and themselves? How would an observer classify them?

- How is variety created and destroyed? What is the right balance of variety– is exploration beneficial or risky?

- What are the interaction patterns?

- What is the mechanism and criteria of success for selection? (“If no mechanism for selection, no mechanism for competition.”) How is this used to promote adaptation?

An exploratory tool of building operations, a la B Victor, would help answer:

- What are open problems in the field?

- Who’s working on which projects?

- What are the fringe ideas?

- What are the process bottlenecks?

- What dominates cost? What limits adoption?

- What future technologies or paradigms would this enable?

- Why make improvements here?

[*] This statement about “direct” is vague on purpose. I’m talking about my own criteria for direct / indirect, not making a judgment about others.

[**] UPDATE: Updated world emissions charts can be found here. Granular Sankey diagram for the US can be found here.